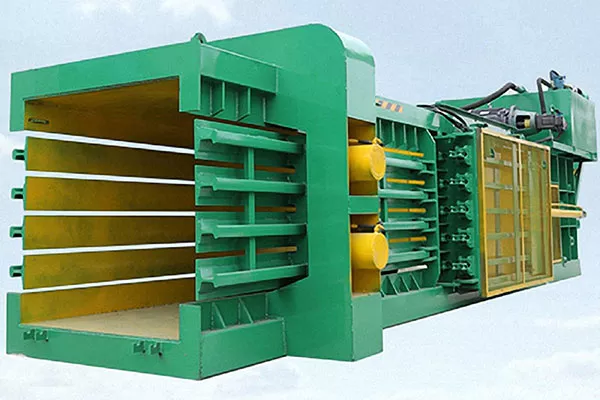

Cardboard Baler Machine

What Is Cardboard Baler Machine

The cardboard baler machine can pack waste cardboard, carton, Corrugated, paper, boxes etc., and compress the bulk material into compact packages through hydraulic devices, which can be placed in rows and saves space, transportation costs and time.

Carton baler machine is defined in accordance with the materials it bales, in fact, it is a set of multifunctional baler, you can also call it a waste paper baler, metal baler, straw baler, cotton baler, plastic baler, etc.

If you are looking for a machine that can help you store the cardboard waste more conveniently, you will not be disappointed in our cardboard baler. A small investment that provides you with convenient and practical space-saving storage.

Types of cardboard baler Machine

Cardboard balers mainly include automatic horizontal balers, semi-automatic horizontal balers, and vertical balers.

Vertical cardboard baler machine

The vertical cardboard baler reduces waste storage space, saves up to 80% of stacking space, reduces transportation costs, and is beneficial to environmental protection and waste recycling.

30 Ton Vertical Cardboard Baler for sale

60 T Vertical cardboard baler

100T vertical baler for cardboard

30 ton single ram vertical baler, hydraulic pressure 30t, power 11kw, packing size about 1000*600*800mm, hydraulic compaction, manual loading, manual button operation.

60 ton vertical cardboard baler, hydraulic pressure 60ton, two rams, power 15kw, the size of the bale is about 1200*800*1000mm, completely maintaining the physical properties of the material, the waste compaction ratio can reach 5:1, two baling roads, convenient operate.

100 ton vertical cardboard baler for sale, hydraulic pressure 100ton, two ram, power 22kw, bale size 1200*800*1000mm, anti-rebound barbs, keep the compression effect, the baler can be automatically popped out, and the pressure plate can be automatically returned.

Semi Auto Horizontal Cardboard Baler VS Fully Automatic Horizontal Baler

semi-automatic cardboard baler Machine

full automatic cardboard baler Machine

The semi-automatic cardboard baler machine requires manual baling. It also means that the baled materials need to be bundled with rope manually. If your baling frequency is not high, you can choose it to save costs.

An automatic cardboard baling machine without manual baling, equipped with a PLC control cabinet and remote control, can control the operation of the machine anytime and anywhere. Automatic rope bundling and extremely high packing efficiency.

With Door Horizontal Cardboard Baler VS without Door Cardboard Baler

With Door Horizontal Cardboard Baler

Without door Cardboard Baler machine

How much is a cardboard baler

We have different models of cardboard baler from small to large, The price of the cardboard baler is mainly determined by the processing capacity and output size, so we can customize the baler according to your requirements at factory price.

Vertical baler price is $1,000 to $5,000; in addition to packaging waste cardboard, it can also package plastic, wool, tires, garbage, bottles, old clothes, etc.

The cost of horizontal balers is more than $10,000, and horizontal cardboard balers generally do not have doors.

How a cardboard baler machine works?

After the material is loaded, you must first send the cardboard into a closed material box, and then use a certain amount of force to push the pressure head to squeeze the material. so that the material forms a bale of a certain size and density. That's how it works!

How to operate a cardboard baler?

Add the material to be packed into the material box, operate the reversing valve handle, close the door cover and lock the door cover to prevent it from floating, perform primary pre-compression, and then advance the side pressure cylinder for secondary compression; the stroke is in place, The main pressure cylinder moves forward and performs final compression. After the main pressure cylinder reaches the system pressure, the pressure is maintained for 3-5 seconds. The main and side pressure cylinders return, pull out the lock head and open the door cover. And that's when you get a cardboard bale.

cardboard baler parts

1. Rack

To support the pillars of the packaging rack and carry the load. Therefore, choose high-quality steel to ensure adequate strength.

2. Box

There are locks on the doors to facilitate the opening and closing of the doors. The floor is made of a thick steel plate, which is convenient to pack with rope and wire.

3. Hydraulic control system

The hydraulic system consists of the fuel tank, plunger pump, electric pump group, multi-way reversing valve, oil pipe, and cylinder. The hydraulic system works in conjunction with electronic components to control every working behavior of the cardboard baler.

4. Master cylinder

The oil cylinder system consists of the main cylinder block, plunger, sealing ring, guide ring, top block, etc., with good sealing performance. The plunger is welded with the seamless steel tube inside the cylinder, which has sufficient strength. The plunger reciprocates in the cylinder. When the plunger rises, pressure is transferred to the top of the box and compresses the material.

5. Main oil supply system

It is the power source for the baler to work. Its performance is critical to the baler. Therefore, it is necessary to use high-quality hydraulic oil over 46#. The system consists of the fuel tank, motor, piston oil pump, reversing valve, relief valve, unloading valve, and filter.

6. Electrical control part

7. Pressure cylinder