Plastic bottle baler machine

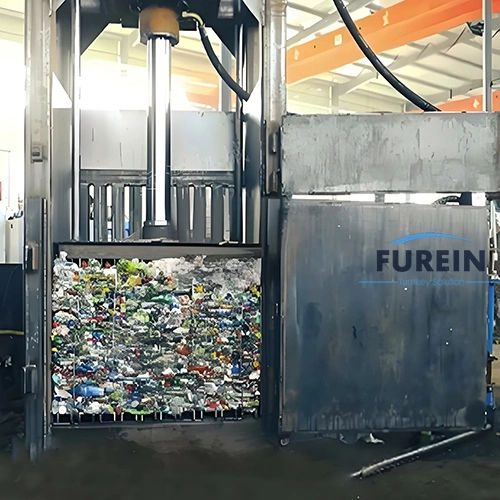

Plastic bottle baler machine is a kind of recycling machinery for compressing and bundling plastic products, which is widely used in logistics, warehousing, manufacturing, recycling and other industries. It mainly compresses and bundles loose materials such as beverage bottles, plastic bags, plastic buckets, etc. into a bale for transportation and storage.

Currently, the plastic bottle baler machine in the market is divided into vertical balers and horizontal balers according to the appearance of the baler.

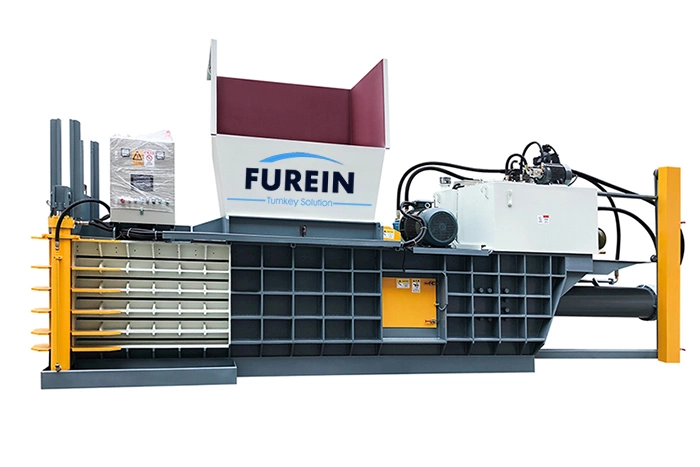

Horizontal plastic bottle baler machine

Horizontal plastic bottle baler display

Effect picture of horizontal plastic baler

Components of horizontal plastic bottle baler machine

- Machine frame: The frame is the framework of the whole baler, supporting all the components and withstanding the pressure and impact generated during the baling process. The frame is usually welded by steel plate or section steel, with sufficient strength and rigidity.

- Hydraulic Plate: The hydraulic plate is the component used to compress the material. The movement of the platen is controlled by hydraulic cylinders.

- Stretching device: Bundling device is used to bundle the compressed materials into packages. Commonly used strapping materials are steel wire or nylon rope. The movement of the strapping device is controlled by hydraulic cylinders or pneumatic cylinders.

- Transmission system: The transmission system transmits power to the hydraulic cylinders or pneumatic cylinders to drive the platen and strapping device.

- Control system: The control system controls the operation of the baler, including the functions of starting, stopping, pressure adjustment and strapping. The control system can be manually controlled or automatically controlled.

- Hydraulic system: The hydraulic system is the core component of the horizontal hydraulic baler, providing power for the pressure plate and strapping device. The hydraulic system usually consists of hydraulic pump, tank, cylinder, valve, and other components.

- Electrical system: The electrical system provides electrical power for the baler and controls the electrical part of the baler. The electrical system usually consists of motor, electric control cabinet, wire and cable and other components.

- Safety device: Safety devices are to ensure the safety of operators, such as safety nets, safety valves, etc.

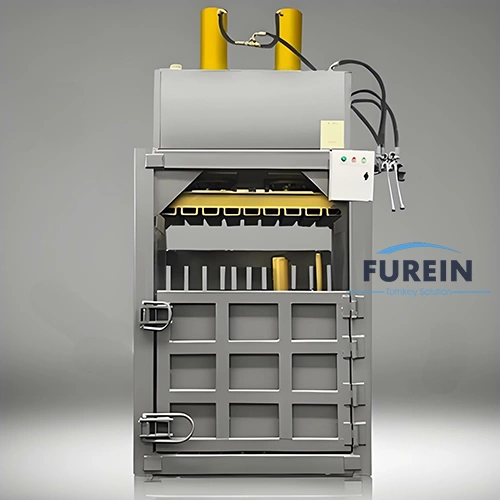

Vertical plastic bottle baler

Vertical plastic bottle baler machine display

Effect of vertical plastic bottle baler

Which different between horizontal and vertical plastic bottle baler?

| Features | Vertical type | Horizontal type |

|---|---|---|

| Feeding method | Vertical direction | Horizontal direction |

| Discharging method | Bottom | Side |

| Applicable material | Large volume | Smaller volume |

| Floor space | Smaller | Larger |

| Operating space | Smaller | Larger |

| Price | Lower | Higher |

How to choose a plastic bottle baler machine?

- Determine your production capacity: For example, how many bales do you need to produce per hour? How big is the plastic bale required? This is very important and will almost always determine the type of machine you will use.

- Your material: the speed and density of baling will vary from material to material. The speed and density of baling will vary from material to material.

- The pressure of plastic baler: baling pressure is one of the important indexes to measure the performance of baler, the higher the baling pressure, the better the baling effect. The pressure of the baler is for your reference only.

- The degree of automation: horizontal balers can realize fully automated operation, and remote control operation, with no need for manual bundling rope. Vertical balers need manual loading and manual tying.

- Your budget, the cost of horizontal baler is 2 times or more than the cost of vertical baler.

- If you are not sure which type of baler to choose, or are confused about how to choose the plastic baler, please leave a message, we will provide you with the solution the first time, with a price list.

The price of plastic bottle balers varies widely, ranging from 2,000 dollars to 20,000 dollars. The specific price depends on the baler's performance, function, brand and other factors. Customers should make comprehensive consideration according to their budget and needs when choosing.

Of course, Furein Machinery is a plastic baler manufacturer that has more than 10 years of experience and can provide you with customized service, tell us what you need, free design and quotation for you to make a plastic baler to your satisfaction.

Power of the baler: The higher the power of the baler, the higher the energy consumption. Generally speaking, the power of a hydraulic baler ranges from 15-100 kW and the energy consumption ranges from 2-5 kWh per kWh.

Types of baling materials: Different types of baling materials have different compression difficulties. The more difficult to compress the material, the more energy required, the higher the energy consumption of the baler. For example, the energy consumption of baling waste plastic is lower than baling cardboards.

Maintenance intervals for hydraulic balers are usually weekly, but this can be adjusted depending on how often the baler is used and the working environment

- Check hydraulic oil level and add hydraulic oil as needed.

- Check hydraulic system seals and eliminate leaks.

- Clean the hydraulic filter element.

- Check the connecting bolts of each component for looseness and tighten the loose bolts.

- Check the electrical system for solid wiring and clean the electrical control cabinet.

Yes, we are a professional manufacturer of recycling machines and can provide you with turnkey solutions. Any machine purchased from our factory is guaranteed for one year, and we will solve any problems during the warranty period for you. Contact us to get the plastic bottle baler machine price with details now.